Audi Q7 Manual: A Comprehensive Guide

Discover detailed Audi Q7 resources, including owner’s manuals, workshop guides, and online access to information dating back to 2008 models.

Welcome to the world of the Audi Q7, a luxury SUV renowned for its sophisticated engineering and driving experience. This comprehensive guide serves as your primary resource for understanding and operating your vehicle effectively. Whether you’re a new owner or a seasoned Audi enthusiast, this manual provides essential information covering all aspects of your Q7.

From detailed explanations of key features and controls to in-depth system guides, we’ll navigate you through the intricacies of the Q7’s technology. You’ll find valuable insights into maintenance schedules, technical specifications, and troubleshooting common issues. Access digital manuals online at ownersmanual.audi.com, or download PDF versions for offline use, particularly for models 2023 and earlier. Explore Audi Original Accessories manuals for further customization and support.

Understanding Your Q7’s Model Year (2025 & Earlier)

Your Audi Q7’s manual is tailored to its specific model year, ensuring accurate information for your vehicle. While this guide offers broad coverage, recognizing year-specific nuances is crucial. Resources are available for older models, including the Typ 4L Q7, with manuals dating back to 2008.

For 2025 and earlier Q7s, accessing the correct documentation is simplified through ownersmanual.audi.com. This platform provides digital versions, while PDFs are readily downloadable for 2023 and prior models. Note that content may vary between generations (4L and 4M), so confirm compatibility. Detailed coverage extends to 285-450+ page manuals, offering comprehensive insights into your Q7’s systems and features. Ensure you select the manual corresponding to your vehicle’s production year.

Key Features & Controls

Explore essential Q7 controls: ignition, parking assistance, and the MMI display, all thoroughly explained within the comprehensive owner’s manual resources.

Ignition System & Key Operation

Understanding your Audi Q7’s ignition system is crucial for safe and efficient operation. The manual details the functionality of the key and keyless entry systems, outlining procedures for starting, stopping, and locking/unlocking the vehicle. It covers various key types, including comfort keys and their specific features.

Detailed instructions explain how to properly insert and remove the key, as well as troubleshooting common issues like key recognition problems. The manual also addresses the operation of the start/stop button and any associated safety precautions. Furthermore, it provides guidance on managing key batteries and remote control functions, ensuring optimal performance of the ignition system. Refer to the manual for specific details related to your Q7’s model year.

Parking Assistance Systems

The Audi Q7 manual provides a comprehensive overview of its advanced parking assistance systems, designed to enhance driver convenience and safety. It details the functionality of features like Park Assist, which can automatically steer the vehicle into parking spaces. Instructions cover activating and deactivating the system, understanding its limitations, and interpreting the visual and audible warnings.

Furthermore, the manual explains the operation of the surround view camera system, offering a 360-degree perspective for improved visibility. It also covers the parking sensors, detailing their range and how to interpret the proximity indicators. Proper understanding of these systems, as outlined in the manual, is essential for safe and effective parking maneuvers, preventing potential damage and ensuring a smooth parking experience.

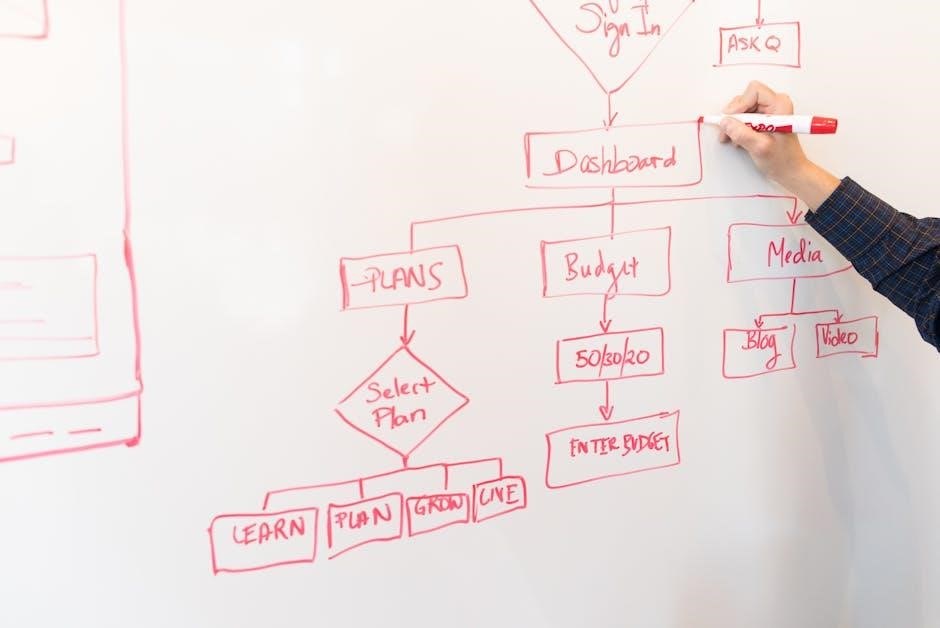

MMI Display & Controls

The Audi Q7’s Multi Media Interface (MMI) is central to vehicle control, and the manual dedicates significant coverage to its operation. It details the physical controls – the rotary dial, buttons, and touchpad – explaining their functions for navigating menus and selecting options. The manual provides clear illustrations and step-by-step instructions for customizing the display, adjusting settings, and accessing various vehicle functions.

Users will find guidance on connecting external devices, utilizing smartphone integration, and understanding the different MMI views. It also explains how to manage user profiles, personalize settings, and troubleshoot common issues. Mastering the MMI, as described in the manual, unlocks the full potential of the Q7’s infotainment and connectivity features, enhancing the driving experience.

MMI Display: Powering On/Off

The Audi Q7 manual provides specific instructions for controlling the MMI display’s power state. Generally, the display activates automatically with ignition on, presenting the Audi logo before transitioning to the main interface. To manually power off the display, users typically press and hold the volume control knob or utilize a dedicated on/off button, if equipped, as detailed in the vehicle-specific guide.

The manual clarifies that completely shutting down the MMI isn’t always necessary; it can enter a standby mode for quicker reactivation. It also addresses scenarios where the display fails to power on, offering troubleshooting steps like checking fuse connections. Understanding these procedures ensures optimal MMI functionality and prevents unnecessary system resets.

In-Depth System Guides

Explore comprehensive guides covering the Audi Q7’s infotainment, navigation, and quick reference features, with detailed manuals exceeding 285 pages.

Infotainment & MMI System Overview

The Audi Q7’s infotainment system, centered around the MMI (Multi Media Interface), provides a sophisticated control center for vehicle functions and connectivity. Manuals detail the system’s description, operation, setup, and adjustments, spanning over 285 pages for the Typ 4L model, dated May 2007.

Users can access detailed instructions on navigating the MMI display, utilizing its features, and customizing settings to their preferences. The system integrates seamlessly with navigation, audio, and vehicle settings, offering a user-friendly experience. Online resources and downloadable PDFs, particularly for models up to 2023, further enhance understanding and troubleshooting capabilities. Explore comprehensive guides for optimal system utilization.

Navigation System Plus Operation

The Audi Q7’s Navigation System Plus, detailed within the MMI navigation system plus operating manual, offers advanced route guidance and map display features. Manuals, specifically those for the Typ 4L, provide comprehensive instructions on system setup, destination entry, route calculation, and map customization.

Users will find guidance on utilizing the MMI interface to manage navigation settings, explore points of interest, and interpret map information. The manual covers functionalities like voice guidance, traffic information integration, and route options. Accessing the online owner’s manual at ownersmanual.audi.com provides supplementary support and troubleshooting tips for optimal navigation system performance.

Understanding the Quick Reference Guide

The Audi Q7 quick reference guide serves as a concise companion to the comprehensive owner’s manual, offering immediate access to frequently used functions and controls. Typically included with the owner’s manual wallet for Typ 4L models, it highlights essential information regarding ignition, parking assistance, and the MMI display.

This guide provides a streamlined overview of key features, enabling drivers to quickly locate instructions for common tasks. It’s designed for on-the-go reference, simplifying operation of the vehicle’s systems. The quick reference guide complements the detailed explanations found within the full owner’s manual, available both in physical and digital formats.

Maintenance & Technical Data

Access crucial details on routine maintenance, engine specifications, dimensions, and overall vehicle care within the Audi Q7 manual’s technical data section.

Routine Maintenance Schedules

Maintaining your Audi Q7 requires adherence to a specific schedule, detailed within the owner’s manual. These schedules outline essential services based on mileage or time intervals, ensuring optimal performance and longevity.

Typical maintenance includes oil and filter changes, brake inspections, fluid level checks, tire rotations, and air filter replacements. More extensive services, like spark plug replacement and timing belt inspections, are scheduled at higher mileage intervals.

The manual provides a clear breakdown of these intervals, differentiating between normal and severe driving conditions. Following the recommended schedule helps prevent costly repairs and maintains the vehicle’s value. Audi also offers digital service reminders through the MMI system, further simplifying maintenance tracking.

Technical Specifications (Engine, Dimensions, etc.)

The Audi Q7 manual comprehensively details the vehicle’s technical specifications. This includes a full breakdown of available engine options – detailing horsepower, torque, and displacement – for each model year. Furthermore, it provides precise dimensional data, covering length, width, height, and wheelbase.

Weight specifications, including curb weight and gross vehicle weight rating (GVWR), are also included. You’ll find information on fuel tank capacity, luggage compartment volume, and towing capacity. Detailed chassis and suspension data are present, alongside steering and braking system specifics.

These specifications are crucial for understanding the Q7’s capabilities and limitations, aiding in informed decision-making regarding maintenance, modifications, and usage. The manual often covers data spanning multiple model years.

Driving & Operational Information

The Audi Q7 manual provides essential driving and operational guidance. It details proper procedures for starting, stopping, and operating the vehicle in various conditions. Information on utilizing driving modes – comfort, auto, dynamic, and off-road – is thoroughly explained, outlining their impact on performance and handling.

Specific instructions cover the use of the transmission, including manual shift mode if equipped. The manual also details the operation of key systems like the parking brake, cruise control, and adaptive suspension. Furthermore, it offers guidance on safe driving practices, load distribution, and towing procedures.

Understanding these operational details ensures optimal performance, safety, and longevity of your Audi Q7. It’s a vital resource for both new and experienced Q7 owners.

Vehicle Care & Cleaning

Maintaining your Audi Q7’s pristine condition is detailed within the owner’s manual. It provides comprehensive guidance on exterior care, recommending appropriate cleaning products and techniques to preserve the paintwork and prevent damage. Interior cleaning instructions cover various surfaces – leather, upholstery, and trim – ensuring their longevity and appearance.

The manual specifies recommended washing frequencies and details proper wheel and tire care. It also addresses seasonal maintenance, such as preparing the vehicle for winter conditions or protecting it from prolonged sun exposure. Furthermore, guidance is given on fluid checks and top-ups, contributing to overall vehicle health.

Following these care instructions helps retain the Q7’s value and ensures a pleasurable ownership experience.

Troubleshooting & Safety

Explore common Audi Q7 issues, safety system details, and warning light explanations within the manual for confident operation and quick solutions.

Common Issues & Solutions

Addressing typical Audi Q7 concerns is simplified with the comprehensive manual. Owners frequently encounter issues with the MMI system, requiring a reset or software update – detailed instructions are provided. Parking assistance malfunctions can often be resolved by recalibrating the sensors, a process outlined step-by-step.

Furthermore, the manual assists in diagnosing ignition system problems, offering guidance on key fob synchronization and battery replacement. It also covers potential issues with the navigation system, including map updates and route calculation errors.

For each issue, the manual presents clear troubleshooting steps, helping owners attempt simple fixes before seeking professional assistance, ultimately saving time and expense. Safety-related concerns always warrant immediate professional attention.

Safety Systems Overview

The Audi Q7 manual meticulously details its advanced safety features. It comprehensively explains the operation of systems like ABS, Electronic Stability Control (ESC), and traction control, crucial for maintaining vehicle control in challenging conditions. Airbag deployment specifics, including frontal, side, and curtain airbags, are clearly outlined, emphasizing passenger protection.

The manual also provides detailed information on driver assistance systems, such as lane departure warning and adaptive cruise control, explaining their functionalities and limitations. Understanding these systems is vital for safe operation.

Furthermore, it covers child safety seat installation guidelines and the proper use of seatbelts, reinforcing the importance of occupant restraint. A thorough understanding of these systems enhances driver awareness and promotes responsible driving habits.

Understanding Warning Lights & Indicators

The Audi Q7 owner’s manual dedicates significant attention to interpreting the vehicle’s warning lights and indicators. It provides a comprehensive guide to each symbol displayed on the instrument cluster, categorizing them by severity – from minor alerts to critical warnings requiring immediate attention.

Detailed explanations cover lights related to the engine, transmission, braking system, and safety features. The manual clarifies the difference between static and flashing indicators, indicating the urgency of the situation.

It also addresses less common warning lights, ensuring drivers are prepared for various potential issues. Proper understanding of these signals allows for proactive maintenance and prevents potential damage, ultimately enhancing vehicle safety and reliability.

Manual Access & Resources

Access digital Audi Q7 manuals online at ownersmanual.audi.com, or download PDF versions for 2023 and earlier models for convenient offline use.

Accessing the Online Owner’s Manual (ownersmanual.audi.com)

Welcome to the Audi online owner’s manual platform! At ownersmanual.audi.com, you’ll find a comprehensive digital resource for your Audi Q7, starting with model year 2008. This platform provides instant access to the vehicle’s operating instructions, features, and important information.

Navigate easily through the digital manual to find details on everything from the ignition system and parking assistance to the MMI display and infotainment system. The online format allows for quick searching and convenient viewing on various devices.

Benefit from up-to-date information and interactive features designed to enhance your understanding of your Audi Q7. Explore detailed explanations, illustrations, and videos to maximize your driving experience and vehicle ownership.

Downloading the PDF Manual (2023 & Earlier Models)

For Audi Q7 models from 2023 and earlier, downloadable PDF manuals are readily available. These comprehensive guides offer a convenient offline resource for accessing vehicle information. You can find these manuals through various online sources, providing detailed insights into your Q7’s operation and maintenance.

Explore sections covering the infotainment system, navigation, and quick reference guides. The PDF format allows for easy storage and access on your computer, tablet, or smartphone.

Benefit from detailed coverage spanning 285 to 450+ pages, depending on the model year and specific features. These manuals are available in English, ensuring clear understanding and effective vehicle management.

Audi Original Accessories Manuals

Enhance your Audi Q7 experience with genuine Audi Original Accessories, each supported by dedicated manuals. These resources provide detailed instructions for installation, operation, and maintenance of your chosen accessories, ensuring optimal performance and safety.

Access these manuals conveniently through the Audi platform, allowing you to download guides specific to your accessory category. Whether it’s for interior enhancements, exterior styling, or technical upgrades, you’ll find comprehensive documentation.

Proper installation and usage, guided by these manuals, guarantee compatibility and maintain the integrity of your Audi Q7’s systems. Explore the full range of accessories and their corresponding guides today!

Detailed Manual Sections

Explore comprehensive sections covering infotainment, MMI operation, technical data, maintenance, driving information, and vehicle care within the 285-450+ page Audi Q7 manuals.

Owners Manual Contents (Typ 4L)

The Audi Q7 Typ 4L owner’s manual provides a wealth of information for vehicle operation and maintenance. Contents include a genuine Audi wallet, the owner’s manual itself, a quick reference guide, and a dedicated operating manual for the MMI navigation system plus, often accompanied by a CD.

Specifically, you’ll find detailed descriptions and operating instructions for the infotainment and MMI systems, covering setup and adjustments. A dated May 2007 edition spans approximately 285 pages, offering extensive coverage. This manual assists owners in understanding all facets of their Q7, ensuring a safe and enjoyable driving experience. It’s a crucial resource for maximizing the vehicle’s features.

Workshop Manual Overview & Availability

Comprehensive workshop manuals for the Audi Q7 are available, combining all repair documentation into a complete resource. These e-books cover the entire vehicle model in meticulous detail, down to the smallest component. They provide technicians and experienced DIYers with the information needed for in-depth repairs and maintenance procedures.

These manuals encompass technical data, maintenance schedules, driving information, control system explanations, instrument details, and guidance on vehicle care. A May 2010 edition, typically around 450 pages, is often available in English, ensuring accessibility for a wide audience. Ordering options for these detailed guides are readily accessible online.

Detailed Coverage: 285-450+ Page Manuals

Audi Q7 manuals offer extensive coverage, ranging from approximately 285 to over 450 pages, depending on the model year and specific system detailed. A 2007 infotainment/MMI manual, spanning 285 pages, provides descriptions, operating instructions, setup guides, and adjustment procedures. These resources delve into the intricacies of the Q7’s advanced features.

Later editions, like the 2010 technical data manual, expand upon this with comprehensive information on maintenance, driving, controls, and vehicle care. These manuals are designed to support both professional technicians and informed owners, ensuring a thorough understanding of the vehicle’s operation and repair.

Language Options (English Availability)

Audi Q7 owner and workshop manuals are available in multiple languages to cater to a global audience. However, specifically, comprehensive technical manuals, covering aspects like maintenance, driving information, and detailed system operations, are readily accessible in English. This ensures that English-speaking owners and technicians have complete access to the necessary documentation.

The availability of English-language manuals is particularly strong for models from 2008 onwards, with digital versions easily found on platforms like ownersmanual.audi.com. This commitment to providing resources in English facilitates easier understanding and maintenance of your Audi Q7.

Manual Condition & Availability

Audi Q7 manuals, both physical and digital, vary in condition depending on age and prior use. Older, physical copies (like those for the Typ 4L) may show signs of wear, but remain valuable resources. Newer models generally have readily available digital manuals in excellent condition via the official Audi website, ownersmanual.audi.com.

Comprehensive workshop manuals, often exceeding 450 pages, are available as e-books, described as being in “good” condition. Access to these detailed guides ensures complete vehicle coverage. Finding specific manuals depends on the model year; 2023 and earlier PDFs are downloadable, while online resources continue to expand.